Manufactures broad range of machine tools

2020年8月3日星期一

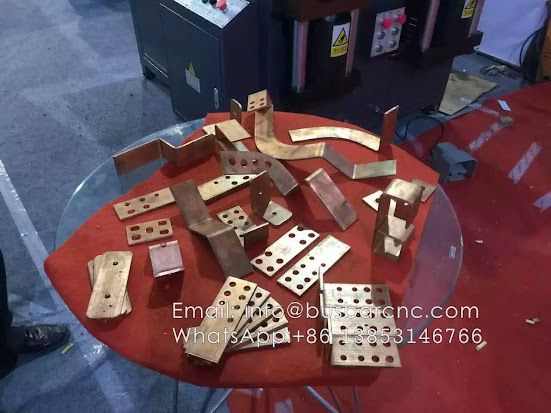

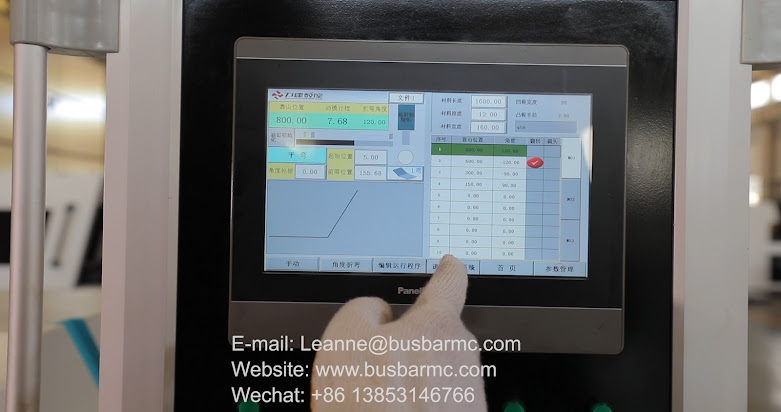

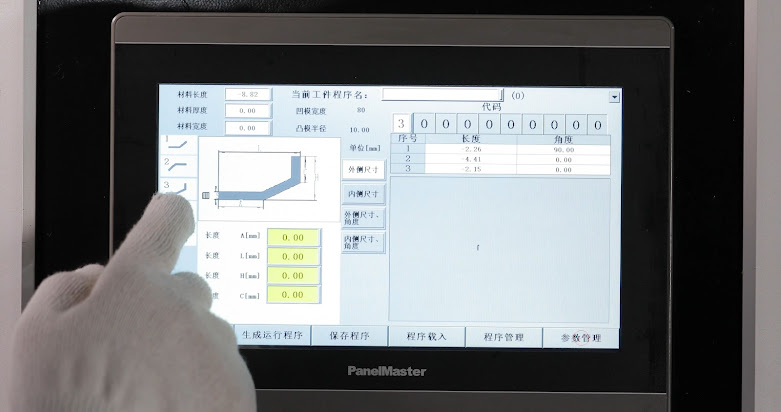

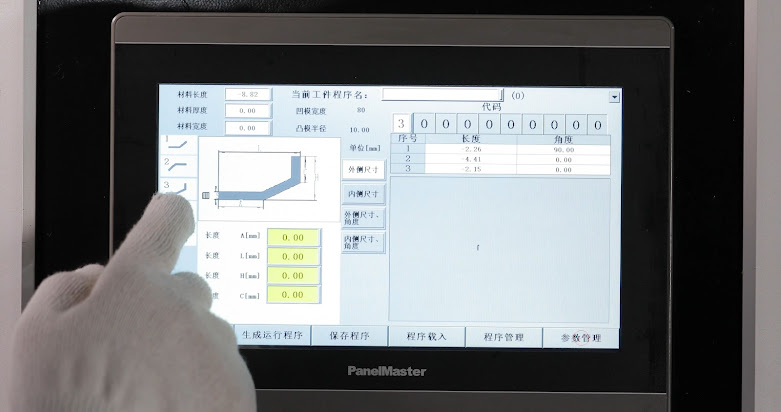

cnc hydraulic punching shearing machinemasu samar da kayan busbar

Mafi ƙarancin lokacin da an yi amfani da daskararrun kusoshin murabba'i wanda

aka saba amfani da shi

dangane

da

kauri mai kauri daga busbars Misali: don tsarin 31.5kA, ich yana ɗaukar 80kA,

kamar don KYN28-12 Switgear a = 27.5cm, don TMY100 × 10 da LMY100 × 10 Sannan: L

jan karfe MAX≤755 (mm). Luminium MAX≤530 (mm). Ana iya gani daga lissafin cewa

don tsarin 31.5KA, idan an karɓi madaidaicin tsarin 100 × 10 bas ɗin nisa, idan

an yi watsi da wasu abubuwan a cikin lissafin ka'idar, dole ne a kula da

tallafin bas a cikin 755mm (530mm) , wanda shine 800mm don girman ɗakin majalisa

Switchgear ba gaskiya bane dangane da aikace-aikacen. Sabili da haka, galibi ba

a amfani da wannan hanyar a cikin 12KV da 40.5KV switchgear da kayan sarrafawa,

amma a cikin kayan lantarki masu ƙarancin wutar lantarki don la'akari da tsarin

tsari da rage sararin samaniya, ana yin amfani dashi sau da yawa a layin

shigarwa da layin haɗin. Dangane da wannan tsari da ke sama, ga bayanai da yawa

na yau da kullun, kamar nisan da ke tsakanin basbars 210mm, 275mm (samfuran

fifiko na wutar lantarki 12KV) 350mm, 400mm, 460mm (kayayyakin samfuran wutar

lantarki 40.5KV), an taƙaita teburin kamar haka: Mafi ƙarancin lokaci (mm)

lokacin da aka saba amfani da bushars rectangular an tsara shi dangane da kauri

gwargwadon sandar. Circuitarancin keɓaɓɓiyar da'irar kA / 4s 31.5 40 Nisa (mm)

210 250 275 350 460 210 250 275 350 460 TMY 100 × 10 Darajar kimiya 2100 2280

2400 2700 3100 1680 1830 1900 2160 2475 Shawarar da aka ba da shawarar 1800 1800

1800 2200 2200 1400 1400 1400 1800 1800 TMY 80 × 10 darajar ka'idoji 1680 1830

1900 2160 2475 1340 1460 1530 1725 1980 Shawarar da aka ba da shawarar 1400 1400

1600 1800 1800 1200 1200 1200 1400 1400 TMY 80 × 8 darajar ka'idoji 1500 1630

1710 1930 2210 1195 1300 1370 1540 1770 Shawarar da aka ba da shawarar 1200 1200

1400 1400 1800 1000 1000 1000 1200 1400 TMY 60 × 6 darajar ka'idojin 970 1060

1110 1255 1440 Neman shawarar 800 800 800 1000 1000 LMY 100 × 10 darajar

ka'idoji 1475 1610 1690 1900 2185 1180 1290 1350 1525 1750 Shawarar da aka ba da

shawarar 1200 1200 1200 1400 1600 1000 1000 1000 1200 1400 LMY 80 × 10 darajar

ka'idojin 1180 1290 1350 1525 1750 945 1030 1080 1215 1395 Neman shawarar 1000

1000 1000 1200 1400 800 800 800 1000 1000 LMY 80 × 8 darajar ka'idar 1050 1150

1205 1360 1560 845 925 970 1100 1250 Neman shawarar 800 800 1000 1000 1200 800

800 800 800 1000 (Tebur 2) Ana shirya mafi ƙarancin (mm) lokacin da ake yawan

amfani da sandunan murabba'i mai kusurwa huɗu tare da juna a cikin hanyar nisa

daga mashaya bas: Shortarancin gajeren zango KA / 4S 31 na'ura mai lankwasawa.5 40 Nisa

(mm) 275 400 460 275 400 460 TMY 100 × 10 darajar ka'idar 755 910 980 605 730

780 Neman shawarar 600 800 800 600 600 600

masana'antar busar katakobusasshen kayan kwastomomi

Tashar tasirin lantarki Don tsarin 31.5kA / 4S, ƙaramin yanki-yanki na ƙasa mai

shinge jan ƙarfe shine: S = 330 × 86.7% = 287mm2 Lissafi bisa ga tsarin da aka

ambata, wanda ya dace da nau'ikan da aka kimanta a takaitaccen ɗan gajeren

lokaci, daidai ga yawancin lokuta da aka saba amfani da su na ɗan gajeren lokaci

tare da kayan aiki, ƙaramin giciye na busba da ƙaramin ƙayyadaddun basali na

tagulla. da kuma busar aluminika da aka yi amfani da su ana nuna su a cikin

Table 1: Tebur 1 Busbar kA / 4s 25 31.5 40 63 80 Musammantawa na tagulla a cikin

kayan aiki 50 × 6 60 × 6 80 × 6 ko 60 × 8 80 × 10 100 × 10 Musammantawa na

tagulla jan karfe 50 × 5 50 × 6 50 × 8 80 × 8 80 × 10 Musammantawa na allon

aluminum a cikin kayan aiki 80 × 6 ko 60 × 8 80 × 8 100 × 8 ko 80 × 10 Bas ɗin

ƙarfe a cikin kayan aiki Imumaramar giciye (mm2) 260 330 420 660 840 Allonum bas

ɗin aluminium a cikin kayan aiki Imumaramar giciye (mm2) 425 540 685 1075 1365

4.2 Tasirin abubuwan lantarki Motar

bas

mai hawa ce wacce take daukar ta yanzu. Lokacin da tsari na gudana ke gudana, ba

makawa zai samar da ƙarfi a kan mashin. Forcearfin da bas ɗin ke motsawa a halin

yanzu yana da alaƙa da yanzu, da siffar motar bas, da nisan da ke tsakanin

motocin. Busbars da aka sanya a layi daya sune

suka

fi yawa a Switgear. Eterayyade matsakaicin matsakaicin busbar (matsakaicin

matsakaici tsakanin goyon bayan biyu) gwargwadon gwargwadon girman lambar da

yake fuskanta Manufa: Matsalar matsananciyar aiki a kan busar dusar

/ cm

≤ abin da ake yarda da laƙabin bas ɗin. Magana: js = 1.76L2ich2 × 10-3 / aW≤y A

cikin dabara: js - nuna damuwa akan bas, kg / cm2; Y-An yarda da matsanancin

wahalar bargon bas, 1400 lokacin da motar bas ta zama jan ƙarfe, da 700 lokacin

da motar bas ta zama aluminium; Nisa-tallafi tsakanin Layi tsakanin basbars

(cm); A — nesa tsakanin juna (cm); W —— Wurin murabba'i mai sigar rarrabuwa mashin kanti, cm3;

Ich-wanda aka fi sani da farko, (KA) Dangane da wannan tsari da ke sama:

Matsakaicin matsakaiciyar motar tagulla itace L copper MAX≤ (1400aw 103 / 1.76

ich2) 1/2 = 892 (aw) 1/2 / ich Matsakaicin matsakaicin shingen allon aluminum

shine Luminan MAX≤ (700aw 103 / 1.76 ich2) 1/2 = 631 (aw) 1/2 / ich Matsalar

sashe na basur rectangular: Gama bas ɗin da aka tsara a sarari sau uku, lokacin

da aka saita motar bas a kwance; ko don bus ɗin da aka shirya sau uku a tsaye,

lokacin da aka sanya bas ɗin a madaidaiciya: (Wato, girman madaidaicin bas ɗin

ya kasance akasin haka, tasirin ƙarfi yana da kyau a wannan lokacin) W1 =

0.167bh2; inda h ke da nisan bas (cm) kuma b shine kauri bus (cm). Maye gurbin W

a cikin tsari mai zuwa don samun L jan karfe MAX≤365h (ab) 1/2 / ich Luminium

MAX≤258h (ab) 1/2 / ich Misali: don tsarin 31.5kA, ich yana ɗaukar 80kA, kamar

don KYN28-12 Switgear a = 28, don matsakaicin iyakar TMY100 × 10 da LMY100 × 10

basbars. Yankin busar yakai 100/10 = 10cm, sannan kauri shine 10/10 = 1cm. L jan

karfe MAX≤240 (cm). Luminumiya MAX≤170 (cm) Ga motar bas-hawa layi sau uku,

lokacin da aka sanya bas daidai; ko don bus ɗin da aka shirya sau uku a tsaye,

lokacin da aka sa bas ɗin leɓe: (Wato, faɗi nisa daga cikin bas ɗin akasin haka

ne, tasirin lantarki ba shi da kyau a wannan lokacin) W2 = 0.167b2h; Sannan: L

jan karfe MAX≤365b (ah) 1/2 / ich Luminium MAX≤258b (ah) 1/2 / ich

bas mai fasa bututun mai(2)busar lankwasawa inji turkey

Lissafin amintaccen bashin Busbar I4 = 2.45Id A cikin dabarar, I4 shine ƙarfin

ɗaukar nauyi na yanzu da keɓaɓɓun ƙaramar tagulla mai lamba huɗu (A). Bayani:

Kafa biyu da kuma sanduna na jan karfe na nufin cewa akwai banbanci tsakanin

albarus ɗin da ke tsakanin firam ɗin biyu. Dangantaka dangantakar tsakanin

bas

din a wani zazzabi na 40 ℃ da zazzabi na 25 ℃ shine: I40 = 0.85I25 A cikin

dabara, I40 shine ɗaukar ƙarfin bas a halin yanzu a 40 ℃ (A); I25 shine karfin

motar bas a halin yanzu a 25 ℃ (A). Dangantaka dangantakar dake tsakanin

saukakkun hanyoyin zirga-zirgar tagulla na tagulla da alumuran alummuka na

wannan ƙayyadaddun yanayi ɗaya ƙarƙashin yanayin zafin yanayi guda ɗaya: IAl =

ICu / 1.3 A cikin dabara, ICu ita ce ke ɗaukar ƙarfin bas ɗin jan ƙarfe; IAl

shine ɗaukar ƙarfin motar bas na yanzu. Misali, gwargwadon tsari da aka ambata a

sama, ƙarfin ɗaukar nauyi na motar TMY100 × 10 ita ce: Zaɓi ɗaya: 100 × 18.5 =

1850A. Littafin bincike shine 1860A. Wannan bayanan ya samo asali ne daga

'Babban Ka'idodin Na'urar rarraba Wutan Lantarki' wanda Ma'aikatar Ruwa da Wutar

Lantarki ta

Masu ba da jan

karfe.bp.blogspot.com/-13DCC8Df5co/XxJXVipMGaI/AAAAAAAAASA/HqILnpasEgA03lwqhNVs-6nBNtoSDfDuQCPcBGAsYHg/s4096/injunan%2Bkatako.jpg"

imageanchor="1" style="margin-left: 1em; margin-right: 1em;">

Masana'antun Masana'antu ta Sin suka

bayar. Biyu Layer: 2 (TMY100 × 10) ƙarfin ɗaukar halin yanzu shine: 1850 × 1.58

= 2923 (A); [Binciken littafin shine 2942A]; Yankunan uku: 3 (TMY100 × 10)

ƙarfin ɗaukar halin yanzu shine: 1850 × 2 = 3700A [Duba littafin don 3780A]

Dukkanin abubuwan lissafin da ke sama suna da kusanci ga bayanai a cikin

littafin, kuma ana iya lissafta amintaccen bas ɗin gwargwadon tsarin da aka

ambata a sama. Bayanin 3.4 (1) Tsarin ƙididdigar lissafin da ke sama ya dace da

sandunan bas na 120 × 12 da ke ƙasa dalla-dalla. (2) Don gwargwadon ƙarfin halin

yanzu na bas mai

fasalin, ana bada shawara don amfani da

ƙarancin tattalin arziki na yanzu don ƙididdige. 4 effectsarfin zafi da warkarwa

na rashin lafiyar basbars 4.1 Tasirin zafin bas 4.1.1 Tasirin zafi na mashin

yana nufin tasirin zafi wanda mashigar motar zata iya ɗauka a ƙayyadaddun yanayi

saboda yawan gudana na yanzu. A cikin juyawa kayan aiki da kayan sarrafawa, yana

nufin ƙimar ɗan gajeran gajeran lokaci (IK) wanda basbar ke ɗauka tsakanin

lokacin da aka ƙayyade a ƙayyadadden amfani da yanayin aikin. 4.1.2 eterayyade

mafi ƙarancin sashin motar bas gwargwadon ƙimar lokacin gajeren lokaci tare da

yanzu Dangane da tsari a cikin GB3906-1991 '3.6-40.5kV AC wanda aka kewaye shi

da kayan aiki mai sarrafawa' [Shafi F]: S = (I / a) (t / θ) 1/2 don ƙayyade mafi

ƙarancin ɓangaren giciye na tashar mota. A cikin dabara: S - imumaramar giciye

mashaya, mm2; I-- wanda aka zana wa gajeran lokaci mai tsayayya da na yanzu, A;

A-Matsalar abu, jan karfe 13, aluminium shine 8.5; T-- wanda aka yiwa gajeren

zango, s; Θ-Yawan zazzabi (K), gabaɗaya 180K ga baƙi masu ɗaukar hoto da 215K na

tsawon 4s. Don tsarin 31.5kA / 4S, ƙaramin yanki ɓangaren gwal mai shinge shine:

S = (31500/13) × (4/215) 1/2 = 330 mm2 Dangantaka tsakanin ƙaramar giciye-yanki

na bas ɗin aluminium da ƙaramar giciye-yanki yanki na motar jan ƙarfe ita ce:

SAl = 1.62SCu A cikin dabara, SAl shine mafi girman yanki-yanki na bas ɗin

aluminum; SCu shine ƙaramin yanki mai shinge na motar tagulla. Don tsarin 31.5kA

/ 4S, mafi ƙarancin yanki-yanki yanki na bas ɗin aluminum shine: SAl = 1.62 ×

330 = 540 mm2 Dangane da tanade-tanaden 7.4.3 a cikin DL404-1997 'Ka'idodin

Fasaha don ba da izini cikin Yanayin Maɗaukaki na Babban Voltage Switchgear',

busar ƙasa da kuma ɓangaren ginin mai jagoran da aka haɗa da shi ya kamata su

iya yin lissafin kashi 87% na ƙirar da aka kimanta kewaye watse halin yanzu na

sunan allo. Minimumarancin yanki mai ƙarancin mashigin ƙasa a ƙarƙashin ɗan

gajeren ikon da'irar tsarin (gajeren gajeren zango shine 4S).

kayan busar kayan aikiservo cnc busbar punch

Dangantaka tsakanin shimfidar busar da ƙarfin ɗaukar nauyi a halin yanzu

Carryingarfin currentarfin yanzu yana sama da waccan lokacin da aka sanya ta a

kwance.

mai hana

baki.bp.blogspot.com/-lhbDtj2LmZA/XxJXVn_f2UI/AAAAAAAAASA/PQJx4Zr_FwAIVPDz7kkelL-e0HfgMBW-ACPcBGAsYHg/s1920/lan%25C6%2599wasa%2Bbusbar%2Binji.jpg"

imageanchor="1" style="margin-left: 1em; margin-right: 1em;">

Gabaɗaya, lokacin da aka shimfiɗa

busasshen ƙasa laɓe kuma nisa ba ta wuce 60㎜ ba, ƙarfin ɗaukar ta yanzu shine

0.95 sau na bas ɗin tsaye, kuma lokacin da nisa ya fi 60㎜, ƙarfin ɗaukar na

yanzu shine madaidaicin 0.92, wannan saboda yanayin zubar da zafi lokacin

tsayawa yafi dacewa lokacin kwanciya. 3.3 valueaukar ƙarfin aiki Dangane da

kayan daban-daban na motar bas, yanzu dauke da karfin da ake da shi ma ya

bambanta a daidai zazzabi. A cikin kayan sauyawa da kayan sarrafawa, katako na

tagulla na katako shine babban bas ɗin aluminika na katako. Carryingimar da take

ɗauke da ita yanzu tana iya kasancewa gwargwadon littattafan zane daban-daban.

Dangane da shekaru da yawa na gwaninta, marubucin ya taƙaita ƙididdigar

ƙididdigar ƙididdigar sauƙaƙe na halin busasshen halin

yanzu

(AC) lokacin da ya miƙe tsaye ta ƙididdigar yawan bas ɗin da ke ɗauke da ƙarfin

halin littattafai daban-daban. Carryingarfin ɗauke da Idarfin A (A) na katako

mai faɗi na kusurwa huɗu a ℃ 40 ℃: Id = k (b + 8.5) h A cikin dabara, b shine

kauri daga cikin busbar (mm); h shine girman sandar busar (mm); k shine

coefficient (A / mm). Dangantaka tsakanin ƙarfin ɗaukar yanzu-bas ɗin farin

ƙarfe mai lahani biyu da kuma busar maraba ɗaya-ɗaya a 40 ℃ I2 = (1.56 ~ 1.58)

Id A cikin dabara, I2 shine karfin iko na yanzu (A) na bas mai jan karfe biyu;

Id shine halin ɗaukar hoto na yanzu (A) na bas mai farin ƙarfe ɗaya. 1.56 ~ 1.58

shi ne mai ba da isasshen aiki, galibi 1.58 don bashin 100 × 10; 1.57 don 80 ×

10, 1.57 don 60 × 6, da 1.56 don 60 × 6. Dangantaka tsakanin ƙarfin ɗaukar

bashin ƙarfe 3 na ƙarafa da sandar tagulla ɗaya na Layer a 40 ℃ ita ce: I3 = 2Id

A

cikin

dabarar, I3 shine ƙarfin ɗaukar hoto na yanzu da keɓaɓɓun fitila mai lamba huɗu

(A). A 40 ℃, alaƙar da ke tsakanin ƙarfin ɗaukar yanzu na busassun ƙarfe na

4-Layer da kuma bas ɗin farin ƙarfe ɗaya (wannan nau'in zaɓi ba da shawarar ba

ne, yana da kyau a yi amfani da busar musamman-mai fasali a maimakon)

busbar punching shearing linealuminum busbar lankwasawa inji

Tunanin yau da kullun na zaɓin tagulla 1 Gabatarwa Busbars, wanda kuma aka sani

da busbars ko bas-dauke da yanzu, wasu nau'ikan ne da ke ɗauke da na yanzu. Anyi

amfani dashi galibi don tattarawa, rarrabawa da watsa wutar

lantarki a cikin na'urar sauya kayan

lantarki da sarrafa kayan don haɗa kayan aikin farko. Dangane da ƙididdigar

bayanan da

suka

dace, yawancin hatsarin gajerun layi na faruwa kai tsaye ko a kaikaice a busar.

Rashin Busbar na ɗaya daga cikin manyan lamuran lalacewa tsakanin faɗuwar kayan

aikin lantarki. Sabili da haka, zaɓin da aka dace da aikace-aikacen bas ɗin yana

da matuƙar mahimmanci. Wannan labarin yana yin bincike na farko, ƙididdigewa da

taƙaitawar abubuwa da yawa da suka shafi basbars a cikin matsakaici na

3.6kV-40.5kV switchgear da kayan sarrafawa. 2 Nau'in busbars A cikin juyawa na

cikin gida da kayan sarrafawa, ana rarraba basbars zuwa rectangular, madauwari,

D-type, U-shaped, da dai sauransu bisa ga giciye-sashe. Daga cikin su, shingen

kusurwa huɗu na giciye iri ɗaya suna da ƙananan juriya da yalwataccen yanayin

ɗumbin zafi sama da madauwari, nau'in D-nau'in, nau'in nau'in, da dai sauransu

Don dalilai irin su ƙarfin ɗaukar hoto na yanzu, kusoshin murabba'i huɗu ana

amfani da su sosai cikin matakan ƙarfin lantarki na 40.5kV da ƙasa. Yankunan

cirko-cirko da D-nau'in suna da sakamako mai kyau na fata da sakamako mai kyau

na anti-corona. Hakanan ana amfani dasu, amma haɗin yana da rikitarwa. U-dimbin

yawa bas ana amfani dashi a cikin kayan aiki tare da buƙataccen sakamako na

halin yanzu da babban ƙarfi, irin su fitinar janareta na janareto. Raididdigar

da take da shi yanzu girma ce, gabaɗaya ta kai sama da 5000A, kuma ƙimar da take

da shi na ɗanɗana halin yanzu (IP) tana da girma, gabaɗaya sama da 50kA. Dangane

da kayan cnc

busbar punching machine, ana iya rarrabe shi zuwa mashigar bas ta jan karfe,

mashaya motar bas, da

mashin ƙarfe na ƙarfe. Daga cikin su,

mashin bus na jan karfe yana da mafi girman halin yanzu-ɗauke da ƙarfi, juriya

mai kyau na lalata ƙarfi da tasiri, kuma shine mafi yawan amfani. Hakanan ana

amfani da busasshen aluminium a cikin ƙaramin yanayi na yau, ba tare da bakin

teku ba da kuma matatun mai. Amfani da shingen ƙarfe shine galibi don lamuran

tattalin arziki, kuma ana amfani dashi galibi a layin haɗin PT. Dangane da

yanayin asalin, ana iya rarrabawa zuwa bas mai wuya da bas mai taushi. Bas ɗin

da ke da sauƙin amfani ana amfani da shi a wuraren da haɗin yanar gizo ba shi da

matsala kuma yana iya ɗaukar wasu sakamako masu ƙarfi, kamar su a cikin kebul

ɗin da ke biye da kewaye. 3 Aikin yanzu na ɗaukar ƙarfin bas 3.1 Ma'anar girman

abubuwan hawa a halin yanzu: Matsayin motar bas na halin yanzu yana nuni da

ƙimar ingancin yanzu da motar zata iya ɗauka a ƙayyadaddun halayen. Bayani:

Babban mai nuna yanayin da aka ƙayyade shine zazzabi. Don sauyawar cikin gida da

kayan sarrafawa, iyakar babba na yanayin zafin jiki shine 40 ° C kuma ƙananan

ƙananan shine -25 ° C.

jan karfe na jan karfe(2)na'urar bugewa

Insulation foda fim yayi lahani da mafita Matsalolin da ke faruwa yayin yin

amfani da isasshen foda an taƙaita su a ƙasa don tunani. 1. Fasahar fim mai rufi

bai isa ba: lokacin yin burodi ya yi tsayi da yawa yayin warkarwa; zazzabi ya yi

yawa; sauran gas

mai

cutarwa an cakuda su a cikin yin burodin; farfajiyar kayan aikin yayi tsauri

sosai; ba a zaɓi hanyar pre-treatment da kyau ba. 2. Nemo fim ɗin shafi: sake

yin burodi sau da yawa; sauran gases gauraye a cikin tanda; yawan yin burodi

lokacin warkarwa. 3. Oel kwasfa a saman fim ɗin shafi: kauri daga cikin murfin

da aka yafa ba shi da kyau; ataminzation na foda bashi da kyau, kuma bindiga mai

feshi yana da tarin foda; yawan zafin jiki na rashin lafiya ya ragu; foda yana

da laima, barbashi na gari sunada yawa; da workpiece aka grounded talauci;

zazzabi na yin burodi ya yi yawa Mafi girma; shafi ya yi kauri sosai. 4. Dimples

a cikin fim ɗin shafi: Aika da kyau, cirewar mai; gurbata iska, gurbataccen

iska, sharewar ruwa cikakke; daidaitawa wurin aiki; samu daga turɓaya ko sauran

rashin lalata. 5. Bubbles suna fitowa a kan fim ɗin shafi: bayan lura da

farfajiyar kayan aikin, danshi ba ya bushe gaba ɗaya, yana barin ruwan saura

kamar abin sha; nakuda, cire tsatsa ba cikakke ba ne; ba

a

cire murfin da bai dace ba; farfajiyar kayan aikin yana da pores; foda shafi ya

yi kauri 6. Fim shafi mara kyau nesa tsakanin gun da aka fesa da aikin aikin

yayi kusa sosai; babban ƙarfin lantarki ba shi da tabbas. 7. Fim ɗin murfin yana

da ƙarfin tasiri mara kyau da adhesion: fim ɗin phosphating ya yi kauri; yanayin

zazzagewa ya yi kasa sosai, lokaci ya yi guntu, don haka curin bai cika ba;

ƙarfe na ƙasa ba a tsabtace ba; shafawa zai rage yawan adon din bayan an nutse

cikin ruwa. 8. Pinholes a cikin fim ɗin shafi: iskar ta ƙunshi abubuwa na

kasashen waje da mai mai; ƙarfin ƙarfin bindigar da aka feshe yana da girma

sosai, yana sa rufin ya rushe; nesa tsakanin gun da aka feshe da kayan aikin na

kusa sosai, yana sa murfin ya rushe; shafi ya yi kauri sosai; fim ɗin fim ɗin ba

shi da cikakken warke. 9. amountaramin yashi yashi ya bayyana a saman fim ɗin

murfi: Sirin ɗin yana toshe ko kwararar iska ba ta da kyau; da ƙaddamar da

bindiga na feshi ba shi da kyau; akwai gari na narkarda foda a cikin dakin

feshin foda; sauran tarkace suna lalata saman kayan aikin. 10. Murfin yana

kashe: farfajiyar kayan aikin ba

su da

kyau, kuma cirewar da lalata abubuwa ba su cika ba; ƙarfin fitarwa na mai samar

da wutar lantarki mai ƙarfin lantarki wanda ba ya isa sosai; workpiece ba ta da

tushe. matsanancin iska ya yi yawa lokacin lullubewa; 11. Rashin wadataccen

foda: bututun da ke bayar da foda ko bututun da ke feshin foda yana toshewa,

kuma foda yana manne da laushi a bututun; matsanancin iska bai isa ba kuma

matsin lambar ba shi da tushe; an gauraya iska tare da mai ko ruwa; canzawa da

samar da foda ba ta da tabbas, Akwai karancin foda a cikin mai samar da foda;

bututun samar da foda yayi tsayi da yawa, kuma juriya tana ƙaruwa lokacin da

foda ta gudana. 12. Foda Foda da mara kyau adsorption: injin janareta bashi da

isasshen ƙarfin lantarki; da workpiece ba da tushe sosai; yawan karfin iska ya

yi yawa; 13. Yawan fitar da foda yana da ƙasa: isasshen matsin iska, ƙarancin

iska; matsanancin karfin iska, gwargwadon iska a cikin cakuda foda da kwarara ya

yi yawa; hawaye na ruwa da gurbatawar mai sun haɗu a sararin sama; da barkonon

bindiga an rufe shi da wani bangare. 14. An toshe bututun da ke fesa foda:

Saboda abu na bututun da ke feshin foda mashin yin lanƙwasa, foda yana da

sauki a bangon bangon; bututun da yake fitarwa yana mai zafi, yana haifar da

foda Lin a cikin bututu ya yi saurin motsa jiki; foda conveying bututu yana

lanƙwasa da kuma gurbata; foda an haɗu da shi tare da ƙarin ƙarancin granular.

15mm tanƙwara jan karfekayan busar

Sandunan jan ƙarfe, sandunan aluminium, sandunan bas, sandunan bas, ƙarancin

motar bas, foda mai ƙarfi da kuma mafita 1. Amfani da samfurori Ruwan namu mai

ba da ƙarfi zai iya rufe saman aikin ƙira ta hanyar murfi ɗumi mai ɗumi, feshin

ruwa, da murfin lantarki don cimma manufar rufi. Da farko tsabtace farfajiyar

kayan aikin don cire mai da sauran ƙazanta, duba ko har yanzu akwai

takaddun da ka cire su, da kuma rufe

sassan da bai kamata mai ruɓi da tef mai ɗauke da zafi ba. Hanyar tsoma bakin

ruwan zafi: aikin aikin an riga ankoma shi zuwa 200 ~ 260C, ana nitsar da kayan

aikin a cikin gadajen da ke gudana na foda na 1 ~ 2 seconds, kauri shine 300 ~

400m (mafi tsayi lokacin ko mafi yawan adadin, mafi girman kauri), sannan Peel

kashe murfin, gwargwadon girman aikin kayan aiki da yawan zafin jiki a lokacin

don sanin ko ana buƙatar gyaran-bayan. Hanyar feshin kwari: aikin workheran ya

zama preheated zuwa 180 ~ 240C, an tura workpiece zuwa dakin feshin foda, an

watsa fitsin foda a kan kayan aiki sannan ya kai kazarar da aka kayyade, sannan

garkuwar tana tsinkaye, gwargwadon girman kayan aiki da yawan zafin jiki a

lokacin. Cakewa. Aikin zafin jiki: Muddin ana amfani da resin buscar epoxy resin

daidai, zai nuna aikin gamsarwa tsakanin -73 o C da 110 o C. Matsaloli guda biyu

da mafita 1. Kuzarin-kumfa da pores suna fitowa a cikin sutturar yayin warkarwa

Sama yana tarko-canji preheating da warke zazzabi Bangarorin ba su da

tsabta-dole ne a tsabtace sassan jiki kafin taron jama'a Samfurin ya lalace

saboda daskararren-daron kwandon da amfani dashi a cikin busasshiyar wuri 2.

Hankali ya yi ƙasa-da samfurin ba zai iya ɗayan sassa ba Bangarorin ba su da

tsabta-dole ne a tsabtace sassan jiki kafin taron jama'a Babu matsi a saman-maye

gurbin kayan Samfurin ba shi da cikakke-duba yanayin zazzabi da / ko daidaiton

tanda; duba lokacin warkewa 3. Rashin tasiri mai ƙarfi-lokacin da aka cutar da

shi, samfurin ya fasa kuma ya fadi sassan Bangarorin ba su da tsabta-dole ne a

tsabtace sassan jiki kafin taron jama'a Samfurin ba shi da cikakke-duba yanayin

zazzabi da / ko daidaiton tanda; duba lokacin warkewa 4. Rashin juriya ta hanyar

rauni-lokacin da bangaren ya yi zafi, waya za'a jona shi kuma a yanka ta hanyar

lullube shi don fallasa shi. Samfurin ba shi da cikakke-duba yanayin zazzabi da

/ ko daidaiton tanda; duba lokacin warkewa 5. Rage jure sinadarai-yayin saduwa

da daskararru, farfajiyar ƙasa ta narke ko ta faɗi ƙasa Samfurin ba shi da

cikakke-duba yanayin zazzabi da / ko daidaiton tanda; duba lokacin warkewa 6.

atingaƙwalwa mai laushi-mai warkewa yana da lalatattun abubuwa busar inji, waɗanda suke da

tsauri da kuma irin orange Samfurin ya

gurbata-duba ruwan da bututun mai; enauki murfin akwati kuma ka nisanta daga

wuraren da aka jika Zafin samfurin ajiyayyen kayan yayi yawa-ajiyar samfurin a

digiri 24 ko ƙasa Mixarancin lokacin cakuda-hade samfurin sosai Lokacin fallasa

samfuran gajere ne gajere lokaci-lokaci na fallasa; ya ƙunshi abun cikin iska

mai yawa; yawan zafin jiki na preheating yayi kadan-yana ƙaruwa sosai yayin

yawan zafin jiki; componentsan aka gyara, ba zai iya riƙe ƙarfin zafin da ake

buƙata ba - ƙaruwa preheating zafin jiki, yi amfani da hanyoyi da dama 7. Babu

isasshen isasshen-kauri mai kauri yana da bakin ciki Zafin samfurin ajiyayyen

kayan yayi yawa-ajiyar samfurin a digiri 24 ko ƙasa Mixarancin lokacin

cakuda-hade samfurin sosai Lokacin fallasa samfuran gajere ne gajere

lokaci-lokaci na fallasa; ya ƙunshi abun cikin iska mai yawa; yawan zafin jiki

na preheating yayi kadan-yana ƙaruwa sosai yayin yawan zafin jiki; componentsan

aka gyara, ba zai iya riƙe ƙarfin zafin da ake buƙata ba - ƙaruwa preheating

zafin jiki, yi amfani da hanyoyi

da

dama Matsanancin ƙarfin lantarki mai ƙarancin ƙarfi-ƙara ƙarfin lantarki; nesa

tsakanin bangaren da mai nema ya yi nisa-sai a hada bangaren kusa; lokacin

rufewa yayi gajarta-mika lokacin shafi; samfurin yana da ruwa-an rufe akwati

kuma nesa da wuraren rigar Shawararmu 1. Zazzabi na ajiya yana da kyau a ƙasa da

digiri 24 2. Guji nesa da wuta kuma ka guji fitowar hasken rana kai tsaye, ya

kamata a sanya shi cikin wuri mai iska 3. Kada a bijirar da foda ɗin a cikin

iska a lokacin da aka yi amfani da shi, ya kamata a rufe ko rufe kowane lokaci

don guje wa haɗar tarkace. 4. Mafi kyawun hanyar adana ita ce: ƙarancin zafin

jiki da yanayin bushewa 5. Kayan aikin da ake amfani da su wajen zanen zanen

dole ne su kasance cikin ƙasa mai kyau domin kawar da wutar lantarki mai tsayi

6. Guji fitarwa ba tare da izini ba na ingin roba 7. A cikin dakin feshin foda,

yakamata a kula da yawan turbaya da ke ƙasa da maida hankali ga haɗari

gwargwadon yiwuwar gujewa haɗarin wuta da fashewar ƙura 8. Sanye take da kayan

aikin keɓaɓɓen foda 9. Kula da ayyukan iska a cikin yanayin aiki 10. Kayan aiki

sun fi dacewa da ƙasa 11. Guji hulɗa da fata na dogon lokaci. Dole ne a wanke

foda da ke manne da fata da ruwa mai sawa. Kada kuyi amfani da solvents 12. Idan

kuna da foda a idanunku, nan da nan ku shafa su da ruwa mai tsabta don aƙalla

minti 10 kuma nemi likita don dubawa

订阅:

评论 (Atom)